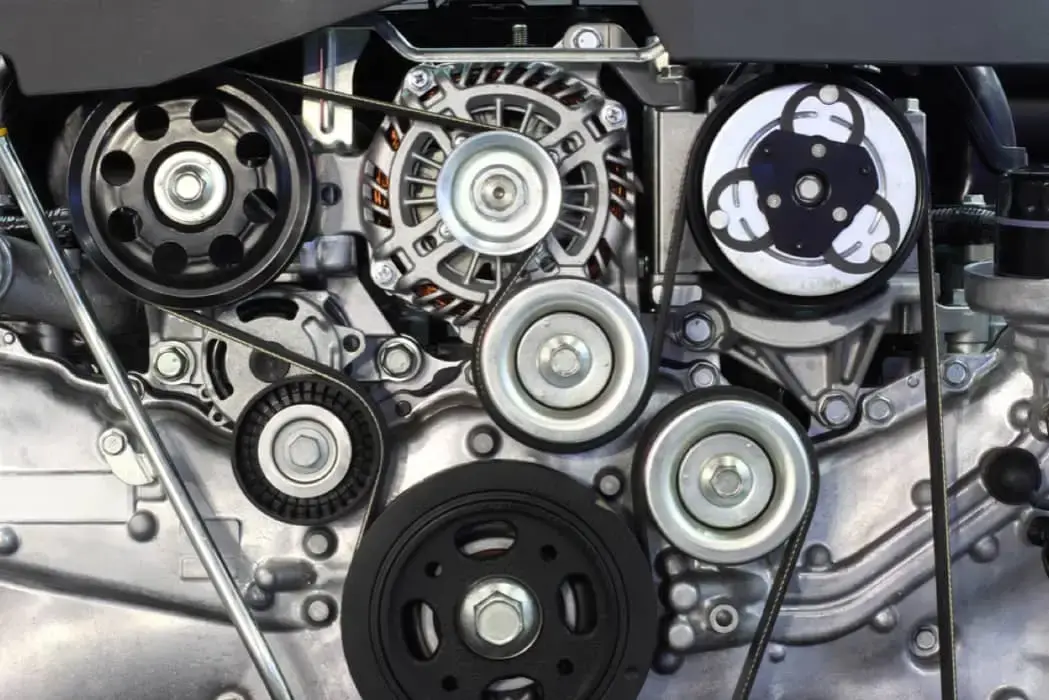

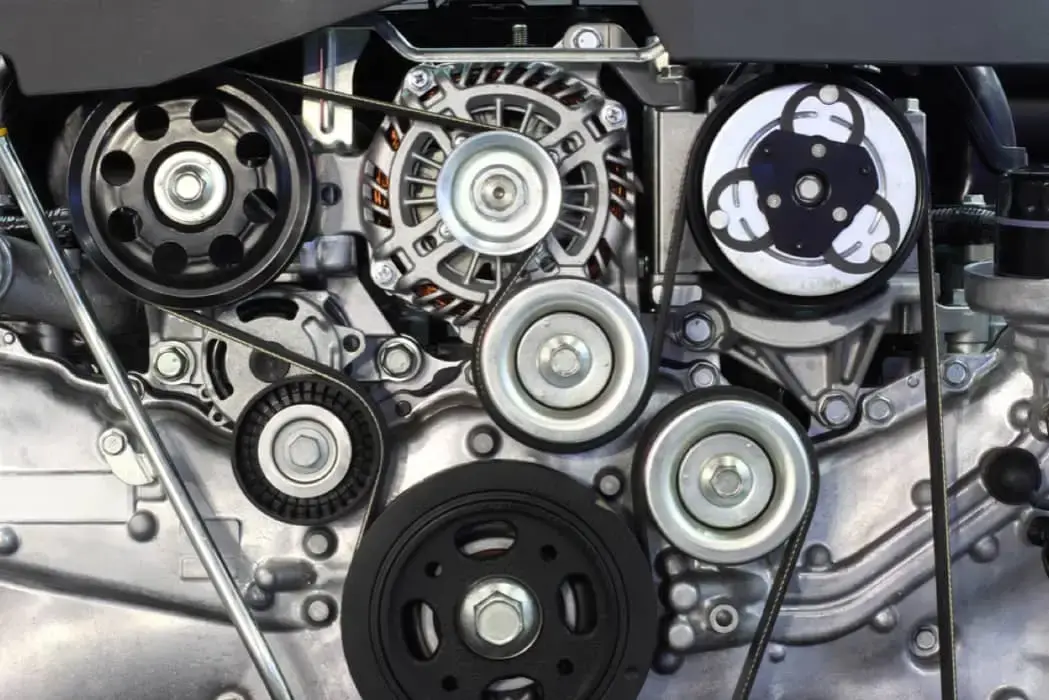

Performance car parts are components designed to enhance mechanical output, control, or durability, and precision matters because even minor dimensional errors can cause performance loss or mechanical failure.

Unlike cosmetic upgrades, these parts interact directly with systems operating under extreme heat, vibration, and load.

Precision manufacturing ensures that dimensions, surface finishes, and material thickness remain consistent across every unit produced.

When tolerances drift, airflow becomes unpredictable, fasteners loosen, and wear accelerates. Poor precision often manifests as vibration, noise, or premature cracking. High precision improves repeatability, load distribution, and confidence during aggressive driving.

Common problems caused by low manufacturing precision include:

- Misaligned mounting points that introduce stress

- Uneven wall thickness that weakens structures

- Rough surface finishes that increase friction and heat

How Are Performance Car Parts Manufactured Today?

Performance car parts are manufactured through a structured process that combines digital design, material processing, precision cutting or machining, and inspection.

Modern production relies heavily on data-driven workflows rather than manual adjustment.

Most manufacturers begin with CAD models and simulations to verify fitment and performance before material is touched. These digital files control machines directly, reducing the risk of interpretation errors.

Once production begins, every step is measured and documented. This approach ensures consistency across batches and enables repeat performance.

The main stages of modern performance part manufacturing include:

- Digital design and simulation

- Material selection and preparation

- Precision cutting or machining

- Surface finishing and post-processing

- Quality inspection and tolerance verification

What Role Does Digital Design Play Before Production Begins?

Digital design defines geometry, tolerances, and function before manufacturing starts.

CAD models serve as the single source of truth for all downstream processes.

Simulation tools allow engineers to test stress, airflow, and thermal behavior virtually. This reduces costly redesigns and shortens development timelines.

Design files feed directly into CNC machines and cutting systems. This digital continuity ensures that the manufactured part matches the intended design with minimal deviation.

What Precision Manufacturing Technologies Shape Modern Car Mods?

Precision manufacturing technologies are advanced production methods that create parts with tight tolerances and repeatable quality.

In automotive modding, multiple technologies are often combined to achieve optimal results. Each method excels at specific tasks depending on material, geometry, and performance requirements.

Understanding these technologies helps explain why high-quality parts perform better and last longer.

CNC Machining for Performance Automotive Parts

CNC machining is a subtractive manufacturing technology that uses computer-controlled cutting tools to remove material and achieve precise shapes.

It is widely used for engine components, brackets, housings, and suspension parts. The process relies on rigid machines, accurate tooling, and controlled motion paths.

CNC machining produces strong metal parts with excellent dimensional accuracy and surface finish. Repeatability is one of its most significant advantages. Every part in a production run behaves the same way under load.

Waterjet Cutting for Automotive Fabrication

Waterjet cutting is a cold cutting process that uses ultra-high-pressure water, often mixed with abrasive, to cut materials without generating heat.

This makes it ideal for performance car parts where material integrity must remain unchanged. Because no heat-affected zone is created, metals retain their original strength and structure. This is especially important for aluminum, titanium, and composite components.

Manufacturers producing brackets, chassis plates, and structural elements often rely on precision waterjet cutting machines to achieve complex geometries with consistent accuracy. Advanced systems such as precision waterjet cutting machines from Techni Waterjet allow fabricators to cut automotive components cleanly while preserving tight tolerances and material properties.

Laser Cutting in Performance Car Manufacturing

Laser cutting is a thermal process that uses focused light energy to melt or vaporize material. It is commonly used for thin sheet-metal parts, such as exhaust components and heat shields.

Laser cutting offers high speed and clean edges when parameters are controlled correctly. It is best suited for applications where speed and repeatability are priorities.

3D Printing for Custom and Lightweight Car Parts

3D printing is an additive manufacturing technology that builds parts layer by layer from digital models.

In performance modding, it is widely used for rapid prototyping and custom low-load components. Its strength lies in design freedom. Complex internal channels and lightweight structures become possible without tooling changes.

What Materials Are Commonly Used in Performance Car Parts?

Performance car parts are made from materials selected for strength, weight, and thermal resistance. Material choice directly influences performance and durability. Selecting the wrong material can undermine even the best design. Precision manufacturing ensures that material properties are fully utilized.

- Aluminum alloys for lightweight strength

- Steel and stainless steel for durability

- Titanium and exotic metals for extreme performance

What Are the Advantages of Precision Manufacturing for Car Mods?

Precision manufacturing offers several advantages that directly impact performance and reliability.

- Improve fitment by ensuring perfect alignment

- Enhance performance through consistent geometry

- Reduce failure risk by eliminating stress concentrations

- Increase repeatability across production runs

- Enable customization through digital workflows

- Support advanced materials requiring controlled processing

What Are the Limitations of Precision Manufacturing in Car Modding?

Precision manufacturing also has limitations that should be understood.

- Increase upfront cost due to advanced equipment

- Require skilled operators and engineers

- Extend lead times for complex parts

- Limit accessibility for small workshops

CNC Machining vs 3D Printing for Performance Car Parts

CNC machining and 3D printing serve different purposes: machining prioritizes strength and accuracy, while printing prioritizes flexibility.

Machined parts typically handle higher loads. Printed parts excel in rapid development and customization. The optimal choice depends on load requirements, material, and volume.

A comparison table should evaluate accuracy, strength, cost, surface finish, and ideal use cases.

How Are Quality and Tolerances Controlled in Performance Parts?

Quality and tolerances are controlled through inspection systems and precise motion control. Modern manufacturers use metrology tools to verify every critical dimension. Servo-driven systems ensure tools follow programmed paths exactly. Accurate motion is essential for maintaining tolerance at speed.

High-performance servo drives from Advanced Motion Controls play a critical role in maintaining positioning accuracy and repeatability in CNC machining systems used to manufacture automotive performance components.

How Much Do Precision-Manufactured Performance Car Parts Cost?

Precision-manufactured performance parts typically range from hundreds to several thousand dollars.

- Material selection

- Manufacturing process

- Tolerance requirements

- Production volume

- Post-processing and inspection

How to Choose the Right Manufacturing Method for Your Car Mod

Choosing the proper manufacturing method requires balancing performance goals with cost and material needs.

- Define load and performance requirements

- Select suitable materials

- Match materials to manufacturing processes

- Evaluate cost versus benefit

- Verify supplier quality capabilities

What Does the Future of Precision Manufacturing Mean for Car Enthusiasts?

The future of precision manufacturing means broader access to high-quality custom parts. Automation and digital workflows are reducing cost barriers. Advanced motion control and cutting technologies will continue to improve consistency.

For enthusiasts, this means better-performing mods with fewer compromises.

Conclusion

Precision manufacturing is the unseen foundation of reliable performance car modifications. From digital design to advanced cutting and motion control, every step affects how a part performs in real conditions.

Understanding these processes helps enthusiasts make informed decisions and avoid low-quality components. As manufacturing technology evolves, precision will remain the defining factor that separates true performance engineering from simple aftermarket upgrades.